The Use of Non-Combustible Materials

Under the new regulation, any and every building work which starts after 20th February 2019 must follow certain specifications. The goal of these is to ensure that no balconies or decks constructed in new buildings are made up of combustible materials. This applies to: New buildings that, – are above 18m, and – are used as sleeping places for people.The new regulation sets out that all the components of the walls, decks, balconies must be tested as non-combustible (European Classification A2-s1, d0 or A1). Non-combustible materials include concrete, metal, stone and ceramics. Materials are classed as non-combustible when they do not contain any material which could burn when exposed to fire.

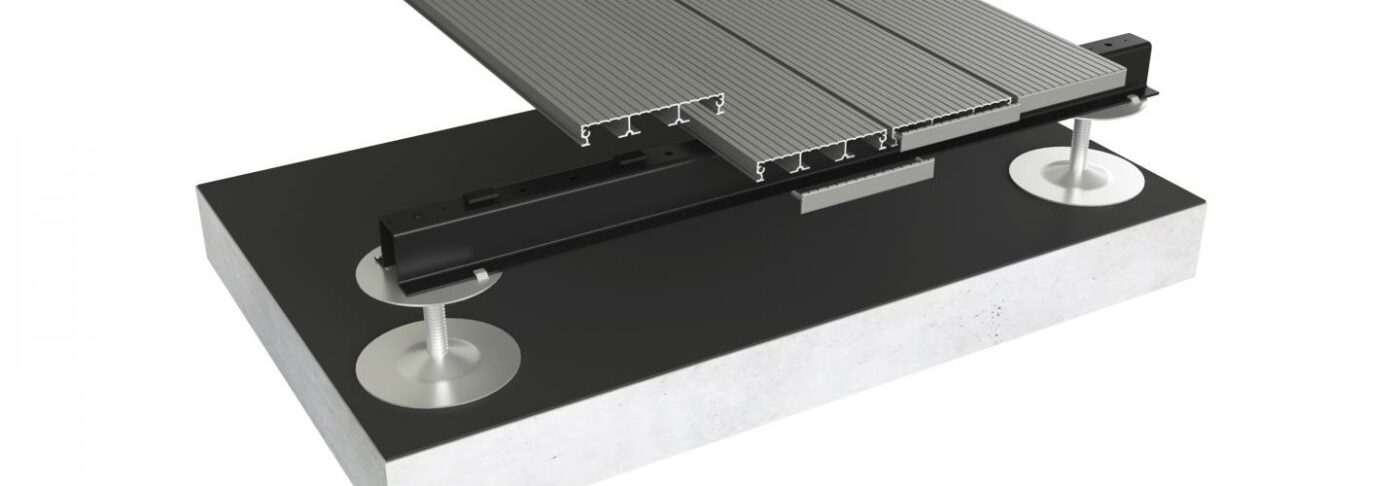

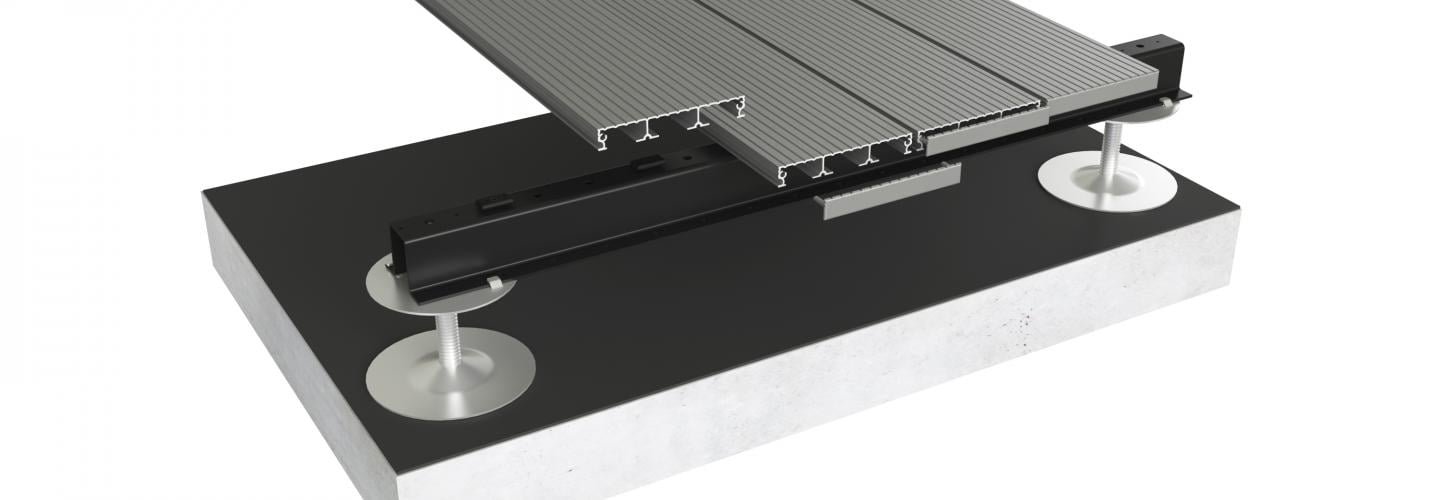

Specifying Decking

The most feasible options are steel and aluminium sheet materials, since plastic will not be allowed, for example as a component of a typical pedestal component of a paving system. Fireproof aluminium decking which is slip-resistant is gaining immense popularity among builders and architects alike. It is also preferred for its ease of engineering, fabrication and forming which make it highly practical. Being 100% recyclable, corrosion-free and low maintenance, aluminium tops the charts for builders and developers, as well as regulatory bodies. All in all, steel and aluminium are viable options which have the necessary non-combustible properties. The new improved regulations have limited some of the readily available decking and flooring materials. For instance, one of the most commonly used up till now has been wood and materials containing wood which cannot be used henceforth. Timber Decking, Polyester Resins and Glass Reinforced Plastic (GRP) are also not permissible options under the new regulation. Additionally, composite decking products are no longer feasible under the new regulations since they do not fall under the Euroclass system categories A2-s1,d0 rated or class A1. Composite decking is combustible. The classifications of materials are assigned based on their individual properties such as; – non-combustibility, – ignitability, – flame spread, – calorific value, – development of smoke and burning droplets. As per the Euroclass system, materials can be divided into 7 categories; A1, A2, B, C, D, E and F. Most materials used in high-rise buildings are Grade A, which is non-combustible. All Grades B (and onwards) are fire retardant or combustible.Fire Retardant vs Non-Combustible

Fire retardant essentially means that they have properties which slow down the fire from spreading. Fire retardant products often contain chemicals to reduce their reaction to ignition or their contribution to fire. Notably, fire-retardant isn’t the same as non-combustible. Therefore only non-combustible decking must be specified in balconies. As in case of fire, balconies can serve as a means of escape for residents until they get help from the fire brigades.

Often, non-combustible materials are confused with fire-retardant materials. In reality, fire-retardant materials are manufactured to resist ignition or limit the speed of combustion. On the other hand, non-combustible materials are those that do not burn or contribute to existing fire breakouts, which is why non-combustible materials should be specified. One such material is aluminium. Aluminium and its alloys, analysed for fire propagation performances provide class1 surface spread of flame in external walls or balcony fires and is intrinsically Class A1 in its unfinished state.